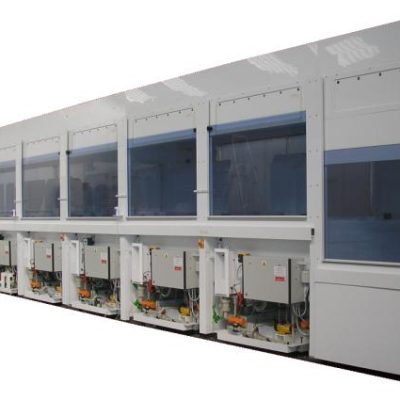

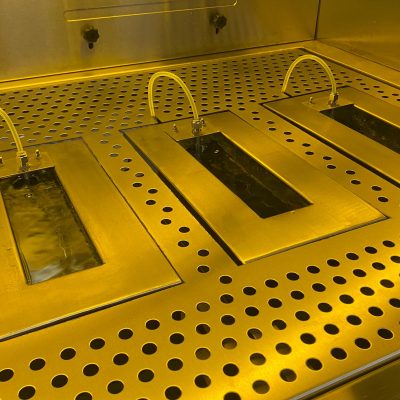

Our Wet Processing Equipment is constructed using high-quality, Fire-Retardant White Polypropylene or FM-approved Thermoplastics for acid and inorganic processes. 304/316-Grade Stainless Steel is used for organic solvent-based processes.

These materials are carefully selected for their durability and compatibility with the most demanding conditions, making them ideal for all cleanroom applications.