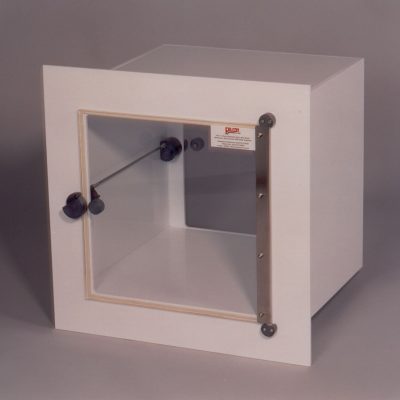

At Felcon, we offer a variety of Transfer Hatches crafted from high-quality materials such as polished 304 and 316 Stainless Steel, Fire-Rated materials, Polypropylene, and Trespa®—a durable high-pressure compact panel. Our units are either standard sizes or bespoke, designed to exact customer specifications rather than off-the-shelf solutions.

Our Felcon Transfer Hatches are designed and manufactured to facilitate the safe and efficient transfer of materials between controlled environments like Cleanrooms, Laboratories and Healthcare facilities.

Our hatches are versatile and customisable, and come in standard sizes or completely bespoke. Each hatch is built to fit specific applications and to suit different environments and needs.

Design

Build

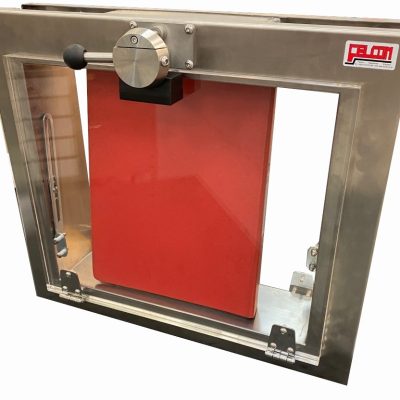

Design Features:

- Interlock systems: Doors are interlocked mechanically or electronically to ensure only one side is open at once—prevents cross-contamination and maintains pressure control

- Door types: Options include hinged (vertical/horizontal), sliding, or automated doors based on operational requirements.

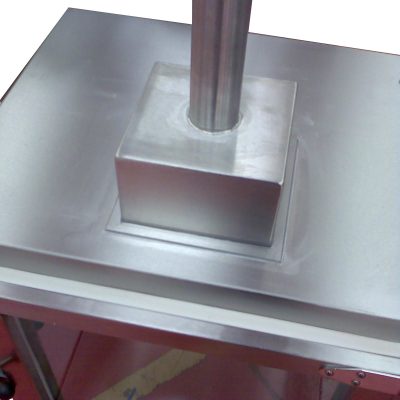

- Cleanability: Fully welded with radius corners; designed for easy cleaning and minimal particle traps.

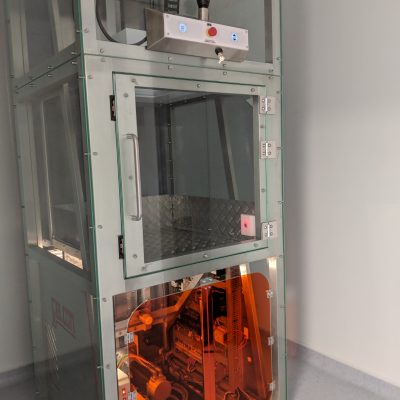

- Optional enhancements: Laminar airflow, inflatable seals, sterilisation systems (UV or VHP), and fumigation compatibility for pharmaceutical-grade installations

Product Types:

Felcon offers several transfer hatch variants, each tailored to different use cases:

- Wall‑mounted static hatches: Ideal for simple pass‑through of materials without trolleys—compact and mounted flush in walls.

- Floor‑standing hatches: Designed for use with trolleys or larger payloads, featuring a double‑skin build for hygiene and durability.

- Active transfer hatches: Equipped with laminar airflow and pressure control, optimised for sensitive cleanroom transfers with air pressure differentials.

- Specialist/custom builds: Including multi-door suites, drum transfer hatches, and configurations with VHP/UV sterilisation or fumigation compatibility.

Clean

Felcon Transfer Hatches are designed for easy cleaning & maintenance. Their non-porous, smooth surface & corrosion-resistant material ensures that the Hatches remain hygienic and fully functional over time. We understand that cleanliness and sterility are critical.

Maintenance

Felcon offer planned service and maintenance solutions for all of our equipment.

Regular maintenance is crucial for the safe and efficient operation of your Transfer Hatch and Containment Equipment.

With Felcon, you can rely on our experience and skills to ensure your equipment complies with British European Standards and Good Manufacturing Practice (GMP).

Our clients can rest assured that their equipment is in safe hands with our highly skilled, service engineers.

Did you know?

Transfer Hatches are known by several different names depending on the industry! Just to name a few:

- “Pass Box” is particularly common in Pharmaceutical and Laboratory Environments.

- “Pass-Through Hatch/Cabinet” is often used when the unit includes shelving, lighting, or filtration systems.

- “Transfer Port/Box” might be used for smaller, more specific transfer openings, especially in Isolators or Containment Systems.

- “Interlocking Hatch” highlights the feature of the Interlock System, which is essential for Contamination Control.