Maximize Your Solar Cell Efficiency with Felcon Wet Benches!

Post by: Rafal Plewko

Sales Manager @ Felcon Limited

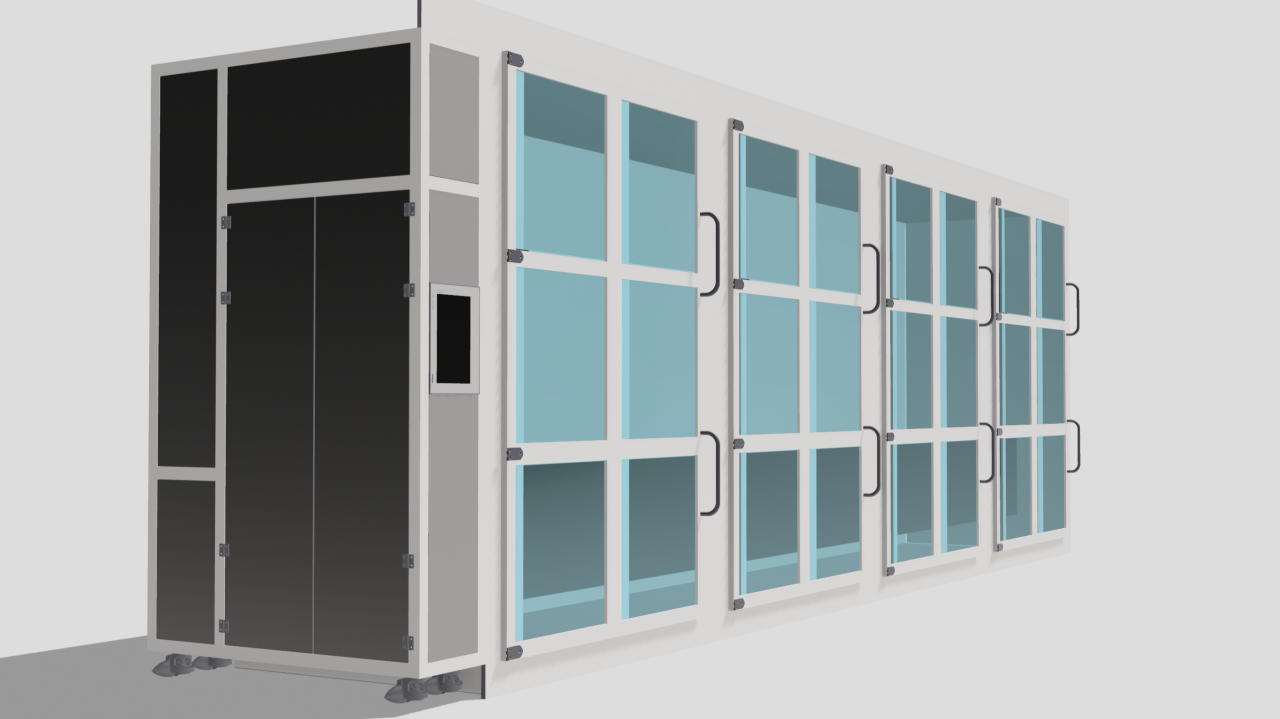

At Felcon Limited , we recognize the vital importance of precision and quality in the manufacturing of solar cells. This is why we provide advanced wet benches specifically designed for solar cell wet processing.

Why Choose Felcon Wet Benches?

- Unmatched Quality: Our wet benches are engineered for superior performance and reliability, ensuring your solar cells meet the highest industry standards.

- Innovative Design: Featuring advanced capabilities and customizable options, our wet benches support various processing steps, including etching, cleaning, and texturing.

- Efficiency: Enhance your production process with our ergonomic, user-friendly designs that streamline workflows and minimize downtime.

- Safety: We prioritize safety by incorporating robust designs and features that protect both your operators and your products

- Felcon Wet Benches Offer:

- Loading and Unloading Buffer: Streamline your operations with efficient loading and unloading systems.

- Process Tank and Overflow Rinse: Enhance your processing capabilities with our advanced tank designs.

- Custom Design: Tailor our solutions to meet your unique needs.

- Alkaline Texturing Process: Our wet benches are ideal for various alkaline texturing processes, including pre-cleaning, texturing, cleaning, and drying.

- Special Requirements: We accommodate any special requirements you may have, ensuring our solutions are perfectly tailored to your needs.

Felcon Wet Processing Stages in Solar Cell Manufacturing:

- Wafer Cleaning: Wet processing is crucial for cleaning silicon wafers to eliminate impurities and contaminants before proceeding with further manufacturing steps.

- Texturing: Wet benches are utilized to texture the surfaces of the wafers, enhancing light absorption by creating a rough texture.

- Etching: This stage involves wet chemical etching to achieve the desired surface properties and dimensions of the wafers.

- Doping and Diffusion: Wet processes are employed to introduce dopants into the wafers, forming the p-n junction that is essential for the functionality of solar cells.

- Anti-Reflective Coating: Anti-reflective coatings are applied through wet processes to minimize light reflection and improve overall efficiency.

Invest in Excellence

Enhance your production capabilities with Felcon’s cutting-edge wet benches, designed to meet the specific needs of the solar cell industry. Our solutions are tailored to help you achieve higher efficiency and better yields, making us a trusted partner in your journey towards sustainable energy.

Ready to take your solar cell manufacturing to the next level? Contact Rafal Plewko today to learn more about our products and how we can support your goals.

+44 7795 361987

Don’t miss out on the opportunity to work with the industry leader in wet processing technology. Send your enquiries now, and let’s innovate together!